The E-INFINITE Flexible phased array probe can inspect bent tubes with one to two lines of multiplexed coils for axial and transverse defects. This probe also has two standard axial coils that support your inspection.

This probe allows for one-pass inspection of defects in all directions using two additional coils angled in the probe body in addition to the conventional axial coils. This probe model is available with several options depending on your application.

#01. Engineering

#02.Design and production of a frame and special tools for producing artificial defects

#03.Part inspection on reception

#04.Creation of artificial defects (side-drilled holes, flat-bottomed holes, semi-elliptical electrical discharge-machined notches)

#05.Dimensional inspection of defects

#06.End-of-manufacturing report

#07.Acceptance

#08. Packaging and shipping

These probes move through tubes in a spiral motion, facilitating the detection and sizing of longitudinal or circumferential defects.

These probes are designed for inspecting formed tubes. The centring cones are made with high-tech plastics designed for optimal friction and wear resistance coefficients.

These probes are designed for inspecting straight tubes. This type of probe may feature a PEEK plastic/stainless steel protective ring or front and rear guides, to extend its service life. They can be fitted with centring cones for improved centring in the tube. These probes are available with a sheath or a clip-connector.

These probes are intended for visual detection and measurement of indications on the internal surface of tubular products. They are equipped with an absolute SAX module to determine positions relative to spacer plates, and with a camera module featuring independently-controllable LED lighting.

Tubes with side-drilled holes, flat-bottomed holes, internal and external grooves, and notches. Plate simulation.

US calibration block featuring Ø1.5 or 3mm side-drilled holes and a 2x2mm groove

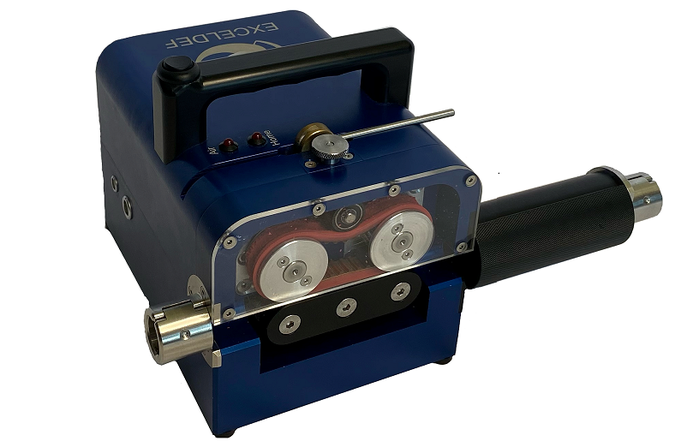

The 2PP200 is a portable, lightweight (6kg) yet tough push-puller incorporating power and control boards for comprehensive functionality.

The blue anodised aluminium casing features an illuminated Power switch, a Forward/Reverse mode selector, five connector ports (AC power, Ethernet, ECT device, encoder and drive gun), and two probe status lights.

This unit allows the inspection of tubes up to 25m in length, at speeds up to 1m/s, with sheaths ranging from 3 to 12 mm in diameter.

This E-INFINITE Rigid phased array probe features a phased array module and 1 conventional "SAX" module for inspecting your tubes for axial and transverse defects. Our wide range of standard probes covers many applications.

#01. Engineering

#02.Kick-off meeting

#03.Material procurement (with material certificate)

#04.Machining

#05. Post-machining UT inspection

#06.Welding and cladding

#07.Creation of artificial defects (FBH, thermal crazing)

#08.Dimensional inspection of artificial defects

#09.End-of-manufacturing report

#10.Acceptance

#11.Packaging and shipping