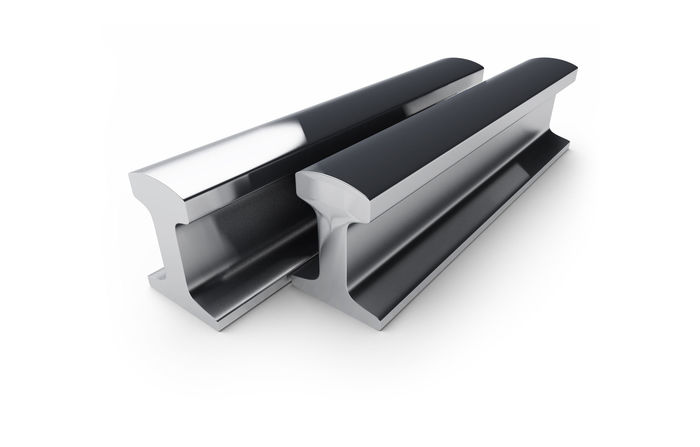

The TTM probe is used for the manual detection and characterization of horizontal and/or transverse cracks of the fungus. The transverse and longitudinal waves of this translator are generated at a frequency of 4MHz.

The TTC probe is used to carry out the first rail inspection. It allows the manual detection and characterization of horizontal and/or transverse cracks of the fungus. It uses a frequency of 2MHz for transverse waves and a frequency of 4MHz for longitudinal waves. The anti-wear bars extend the life of the translator. This translator is easy to use on the EXCELDEF rod.

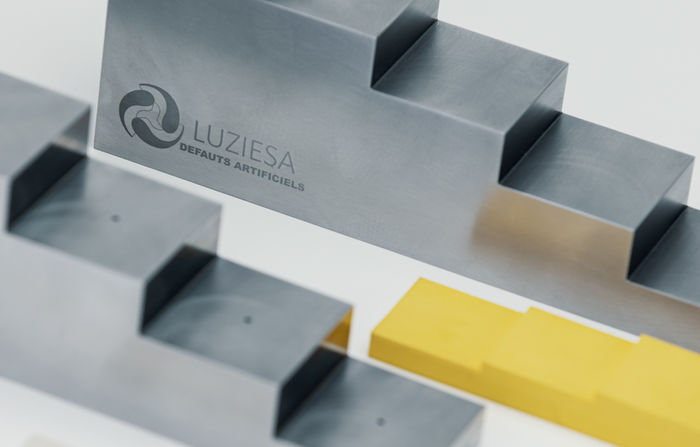

Luziesa can create artificial defects such as notches, side drilled holes and flat-bottomed holes in rails up to 18 m long, in our workshops or at your production facilities.

Rotating-disk sensors are used with mechanical rotation devices that operate at very high speed. These sensors use differential reflection coils for rail foot inspections.

US calibration block, fully configurable to suit your requirements. The number of steps, step dimensions, number of artificial defects and defect dimensions can all be custom-specified. Flat-bottomed hole: Ø0.4mm or larger. Calibration notch: mouth width of 0.1mm or larger.