Les sondes tubes

Our phase array probes contain multiple coils, increasing the probe's total coverage. This advantage saves valuable time during inspections. These sets of coils can be connected, in groups, to the various channels of eddy current inspection instruments; alternatively, they can be multiplexed to enhance sensor resolution.

This E-INFINITE Rigid phased array probe features a phased array module and 1 conventional "SAX" module for inspecting your tubes for axial and transverse defects. Our wide range of standard probes covers many applications.

The E-INFINITE Flexible phased array probe can inspect bent tubes with one to two lines of multiplexed coils for axial and transverse defects. This probe also has two standard axial coils that support your inspection.

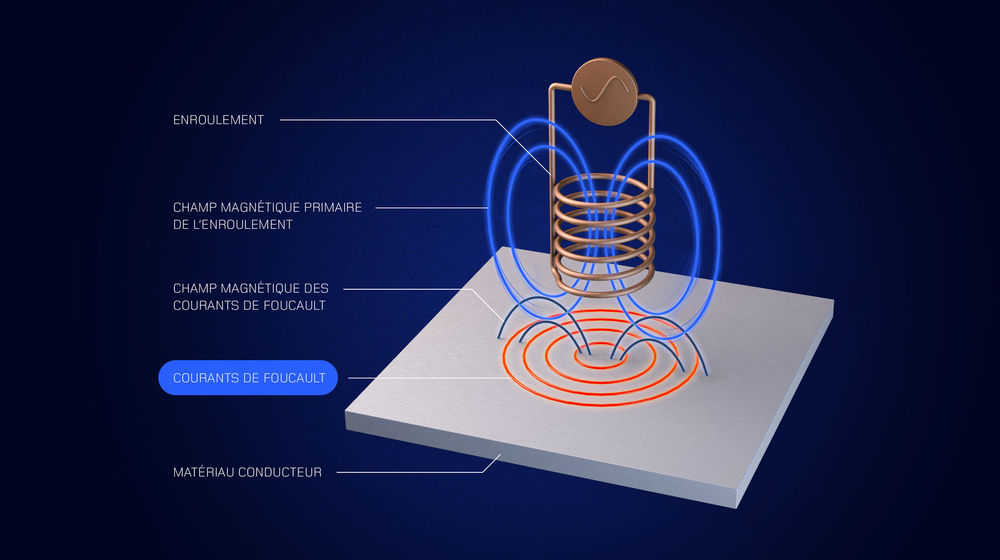

The technique harnesses a phenomenon known as electromagnetic induction, in which a magnetic field is generated by passing a current of variable intensity through a coil. On contact with a metal component, this field induces swirling "eddy" currents in the component. In accordance with Lentz's law, these eddy currents in turn emit a secondary magnetic field, opposing the field that initially created them. Any irregularities within the material (such as defects or fluctuations in electrical conductivity or magnetic permeability) disrupt the eddy currents' flow, influencing the secondary magnetic field and in turn altering the primary field inside the coil. A measuring instrument specially designed for ECT inspections detects variations in impedance, indicative of irregularities within the material. Eddy current testing is used across a broad spectrum of applications, which can be organised into the following categories: In-tube inspections using an internal probe; tube or bar inspections using a circling probe; surface probes; drilled hole probes; and special-purpose probes.

These probes are designed for inspecting straight tubes. This type of probe may feature a PEEK plastic/stainless steel protective ring or front and rear guides, to extend its service life. They can be fitted with centring cones for improved centring in the tube. These probes are available with a sheath or a clip-connector.

These probes are designed for inspecting formed tubes. The centring cones are made with high-tech plastics designed for optimal friction and wear resistance coefficients.

These probes move through tubes in a spiral motion, facilitating the detection and sizing of longitudinal or circumferential defects.

These probes feature a quick-connector, a lightweight plastic body and a reinforced measurement head operating in differential mode. Our probes attach quickly and easily to our driver gun, with extensions available in various lengths to suit your application.

This probe allows for one-pass inspection of defects in all directions using two additional coils angled in the probe body in addition to the conventional axial coils. This probe model is available with several options depending on your application.

Les technologies Champs Lointains et Champs Proches, tout comme la technologie Courants de Foucault, sont des techniques d’inspection par voie électromagnétique, spécialement conçus pour le contrôle de tubes ferromagnétiques. Dans cette méthode, une partie du champ généré par la bobine d’émission est guidée par les parois du tube ferromagnétique. Toute variation sur les parois du tube modifiera la concentration des lignes de champs guidées. Une seconde bobine de réception en amont de la première bobine viendra détecter ces variations de champ pour remonter à des imperfections dans les parois du tube. Cette méthode est particulièrement adaptée aux échangeurs thermiques composés de tubes ferromagnétiques des industries nucléaires, ou pétrochimiques.

Our remote field probes larger than 26mm in diameter are flexible, to facilitate inspection tasks. Each of the probe's constituent modules is centred by means of interchangeable brushes, and modules are interconnected by hollow shafts with a high tensile strength.

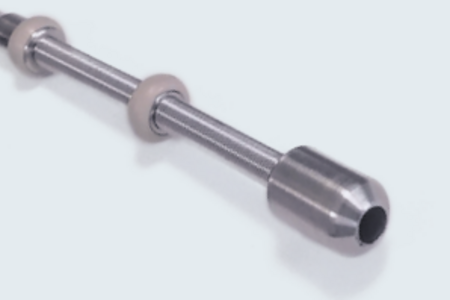

Our rigid probes are available in a range of diameters from 9mm to 26mm. These probes are protected by a stainless steel sleeve that considerably increases their service life.

La méthode d’inspection par champ proche est une méthode d’inspection de la même famille que la méthode des Champs Lointains. En Champ Proche, la bobine de mesure est rapprochée de la bobine d’émission pour analyser les variations du champ magnétique dans la zone champ proche. Elle permet donc de mettre en évidence des défauts situés sur la paroi interne du tube. Cette technique est particulièrement appréciée pour la détection de défaut dans des tubes à ailettes en pétrochimie.

Our near field probes larger than 26mm in diameter are flexible, to facilitate inspection tasks. Each of the probe's constituent modules is centred by means of interchangeable brushes, and modules are interconnected by hollow shafts with a high tensile strength.

Our range of rigid probes starts at 9mm diameter. These probes are protected by a stainless steel jacket to considerably increase their lifespan. Both the CL and CP methods can be combined to inspect both the inside and outside of ferromagnetic tubes in a single pass.