The absolute contact sensor is used for manual crack control. It is also used on a fixed fixture in an automated control station.

This sensor can be used to inspect the rim profile for cracks in the spokes. It features two coils shaped to the rim.

The conductivity probe is used to measure the electrical properties of a material in order to sort matter or to study the lifespan of a part that is heating up. This probe is also used to measure the thickness of a coating.

The E-PADDED sensor can be used to inspect complex geometries such as welds or aircraft wheels: its applications are very diverse. It is composed of 3 parts, the case, the support and the flex. The support can be either semi-rigid or foam. You can easily unhook the flex in order to change it or change the support. This sensor is ideal for crack mapping.

Luziesa produces artificial defects for US inspections performed during production. Luziesa is equipped to produce flat-bottomed holes in diameters of 0.2mm and above, in any type of part used in the automotive sector.

These sensors are used to inspect piston chambers in a static setup as part of an automatic inspection station. They are equipped with multiple coils, to allow zone-by-zone inspections.

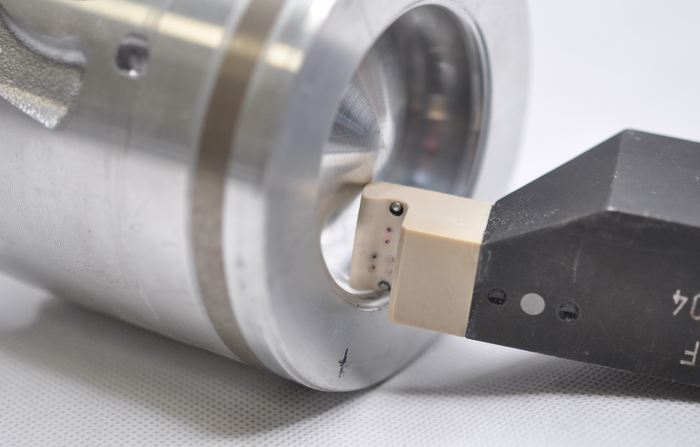

Our contact sensors, designed for manual crack inspection or static installation in an automatic inspection station, feature a stainless steel body and a PEEK measuring head, considerably enhancing their service life

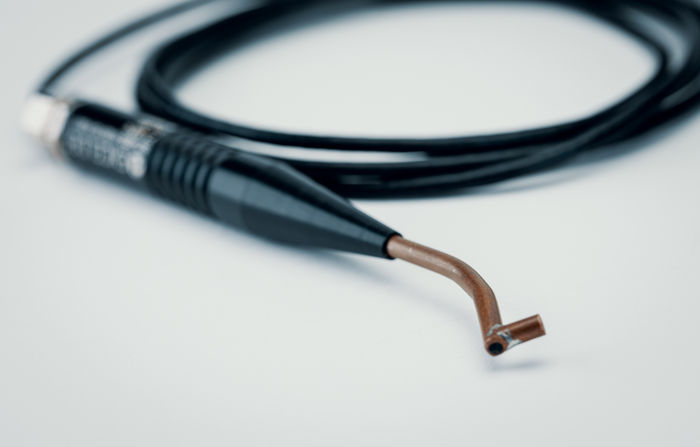

Twisted-stem surface sensors can be used to obtain an ergonomic working position, or to access hard-to-reach areas. This type of shielded sensor is characterised by small coils and a small-diameter casing designed for higher frequencies. They are most often used for detecting surface cracks.