The absolute contact sensor is used for manual crack control. It is also used on a fixed fixture in an automated control station.

Le E-Spin est équipé d’une prise rapide compatible avec toutes les sondes rotatives. Il permet l’inspection de tous types d’alésages. Le boîtier est en aluminium anodisé bleu avec un interrupteur lumineux de déclenchement de rotation, une prise de connexion sur rallonge d’appareillage et un indicateur de défaut.

Ultra-flexible plug-in sensor that offers a wide range of applications. The upper part attaches to different flexes designed with real spools. This sensor produces high-quality signals and better detection capabilities. These sensors are suitable for detecting surface corrosion, subsurface indications, and surface cracks.

This sensor can be used to inspect the clean weld bead and the HAZ for cracks. Its orthogonal winding offers an alternative to penetrant testing. It is possible to add a bracket to ensure that the sensor is placed on the cord.

These probes are used to inspect steam generator tubes on nuclear submarines. They are equipped with a flexible linkage that allows them to pass through small-radius U-bends.

These probes feature a quick-connector, a lightweight plastic body and a reinforced measurement head operating in differential mode. Our probes attach quickly and easily to our driver gun, with extensions available in various lengths to suit your application.

Our SRD probes are equipped with FISCHER 4-pin quick connectors, and operate using the differential reflection principle. Rigid and flexible versions are available, with a stainless steel or PEEK plastic measuring head. Expanding, variable and spherical measuring heads can also be supplied, to suit the customer's requirements.

These probes move through tubes in a spiral motion, facilitating the detection and sizing of longitudinal or circumferential defects.

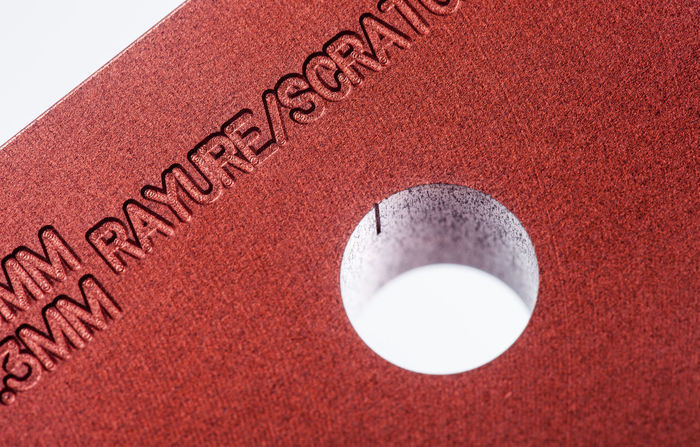

Diameter range: Ø3mm (H7) and up. Holes may also be machined straight, milled at 100°, or with a spherical mouth. Artificial defects: Rectangular notch, quadrant notch, vee-notch

Our extensions are designed to be rapidly inserted between the gun and probe for inspecting threaded fittings.

Our tap and thread probe driver gun features a fully-integrated power and control system to facilitate the inspection of nuts and screws.

The E-Spin features a quick-connect coupling compatible with all rotating probes. It facilitates the inspection of all types of drilled hole. The blue anodized aluminium casing is fitted with a rotation control switch (with status light), an instrument extension connector, and a fault indicator.

Our guide hoses ensure that probes move smoothly between the probe driver and the inspected tube. Manufactured using tough, lightweight materials, they are designed to withstand pressures of up to 3 bars. Available in several lengths: 400mm, 800mm and 1200mm as standard.

These high-torque motorised sheaths spin rotating probes at speeds of up to 12 revolutions per second. We can supply either DC motors or brushless motors for additional torque.