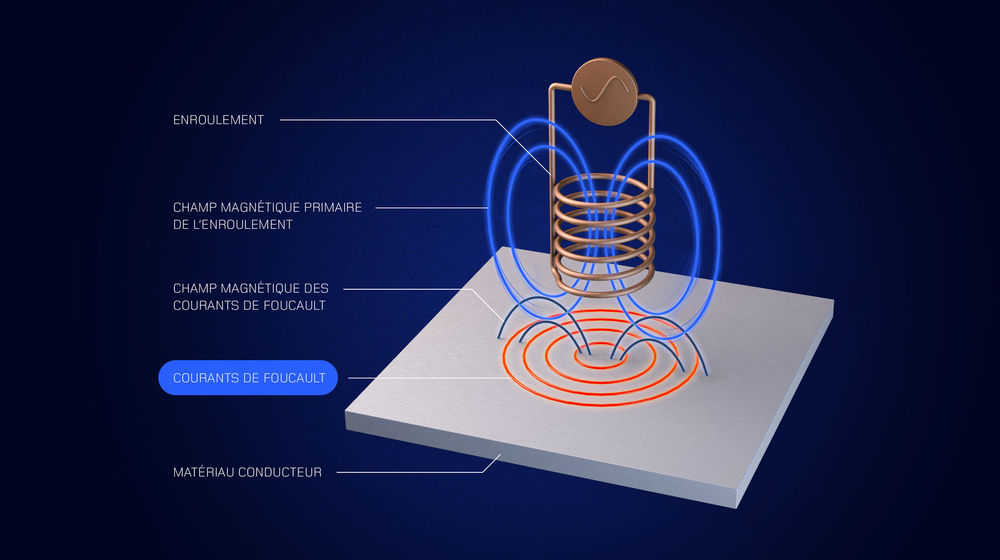

The technique harnesses a phenomenon known as electromagnetic induction, in which a magnetic field is generated by passing a current of variable intensity through a coil. On contact with a metal component, this field induces swirling "eddy" currents in the component. In accordance with Lentz's law, these eddy currents in turn emit a secondary magnetic field, opposing the field that initially created them. Any irregularities within the material (such as defects or fluctuations in electrical conductivity or magnetic permeability) disrupt the eddy currents' flow, influencing the secondary magnetic field and in turn altering the primary field inside the coil. A measuring instrument specially designed for ECT inspections detects variations in impedance, indicative of irregularities within the material. Eddy current testing is used across a broad spectrum of applications, which can be organised into the following categories: In-tube inspections using an internal probe; tube or bar inspections using a circling probe; surface probes; drilled hole probes; and special-purpose probes.

These probes feature a quick-connector, a lightweight plastic body and a reinforced measurement head operating in differential mode. Our probes attach quickly and easily to our driver gun, with extensions available in various lengths to suit your application.